TM 11-5826-225-35

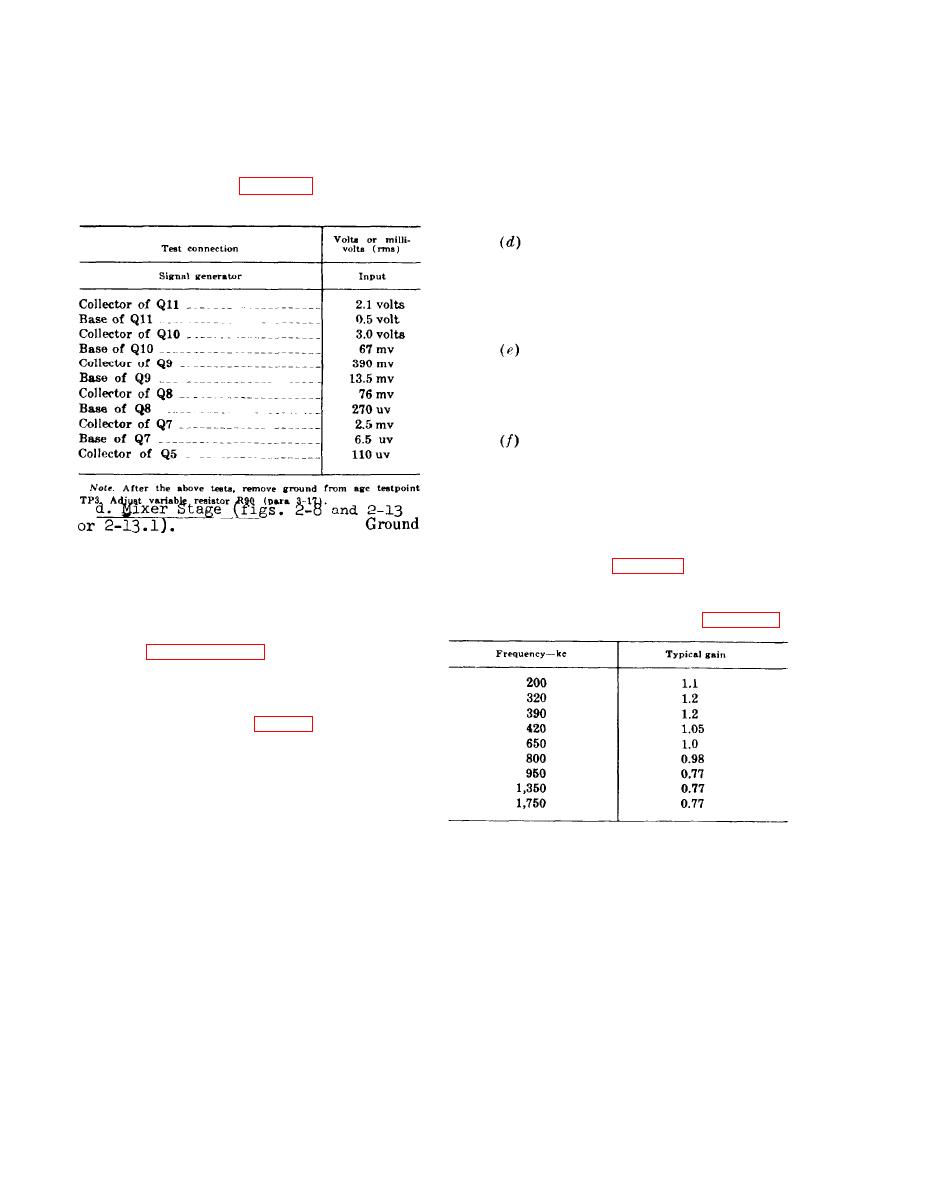

Input column. These voltages in the Input

190- to 400-kc range and tune to

column are the signal voltage required to ob-

200 kc. Set BFOOFF switch to

tain an indication of 5 volts dc on the vtvm. If

BFO and adjust signal generator

the voltage differ abnormally, check the IF

for zero beat. Then set BFO--OFF

t r a n s f o r m e r s and if necessary, use further

switch to OFF

isolating techniques (para 28) to determine

(c) Connect vtvm to cathode of audio

detector CR1. Ground agc testpoint

the defective component.

TP3.

Adjust signal generator output level

to produce an indication of 5 volts

dc on the vtvm. Record the signal

generator output voltage required

to produce the vtvm reading of 5

volts d c .

Determine mixer gain by dividing

the signal generator voltage applied

to the base of Q7, to produce 5 volts

dc on the vtvm as in d above, by the

value obtained in (d) above.

Typical mixer gain values at various

frequencies are listed in the follow-

ing chart. Repeat the above proce-

dures for the remaining frequencies

listed in the Frequency column. If

mixer gain differs appreciably from

agc testpoint TP3 and turn variable resistor

t h e chart, use further isolating

R90 fully clockwise. Set vtvm for measuring

techniques (para 28) to isolate the

dc voltages from O to 5 volts. Connect positive

defective component. After these

test lead to cathode of audio detector CR1 (fig. 2-14 o r

tests, remove the agc ground con-

2-14.1) and negative test lead to receiver chassis.

nection and adjust R90 (para 317).

Set test set and control unit controls as out-

lined in paragraph 26b(1). Set RF signal

generator output signal to 142.5 kc modulated

30 percent at 400 cps. Adjust output level to 6

or 7 microvolt and apply signal to the base of

output signal until vtvm indicates 5 volts dc.

The signal generator output signal required to

produce this de voltage level should be in the

range of 6.5 to 7 microvolt. Record this refer-

ence level for use in the following tests. Remove

signal generator and vtvm connections.

(2) Gain of mixer at RF frequencies.

(1) Gain of mixer at IF frequency.

(a) Turn variable resistor R90 fully

clockwise. Ground test point TP--3.

(a) With signal generator set as shown

(b) Set RF signal generator for a 200-

above, use the 50-ohm probe and

kc output signal at a level of 6 or 7

apply 142.5-kc RF signal to the

m i c r o v o l t . Using 50-ohm probe,

junction of C29 and contact 3 of

apply signal to the junction of C29

front switch wafer S11 labeled

and contact 3 of front switch wafer

TP4 in figure 5-10 or 5-10.1.

S1-I labeled TP-4 in figure 5-10

(b) Set control unit range switch to the

or 5-10.1.

2-26 C h a n g e 1

Previous Page

Previous Page