TM 11-5826-225-35

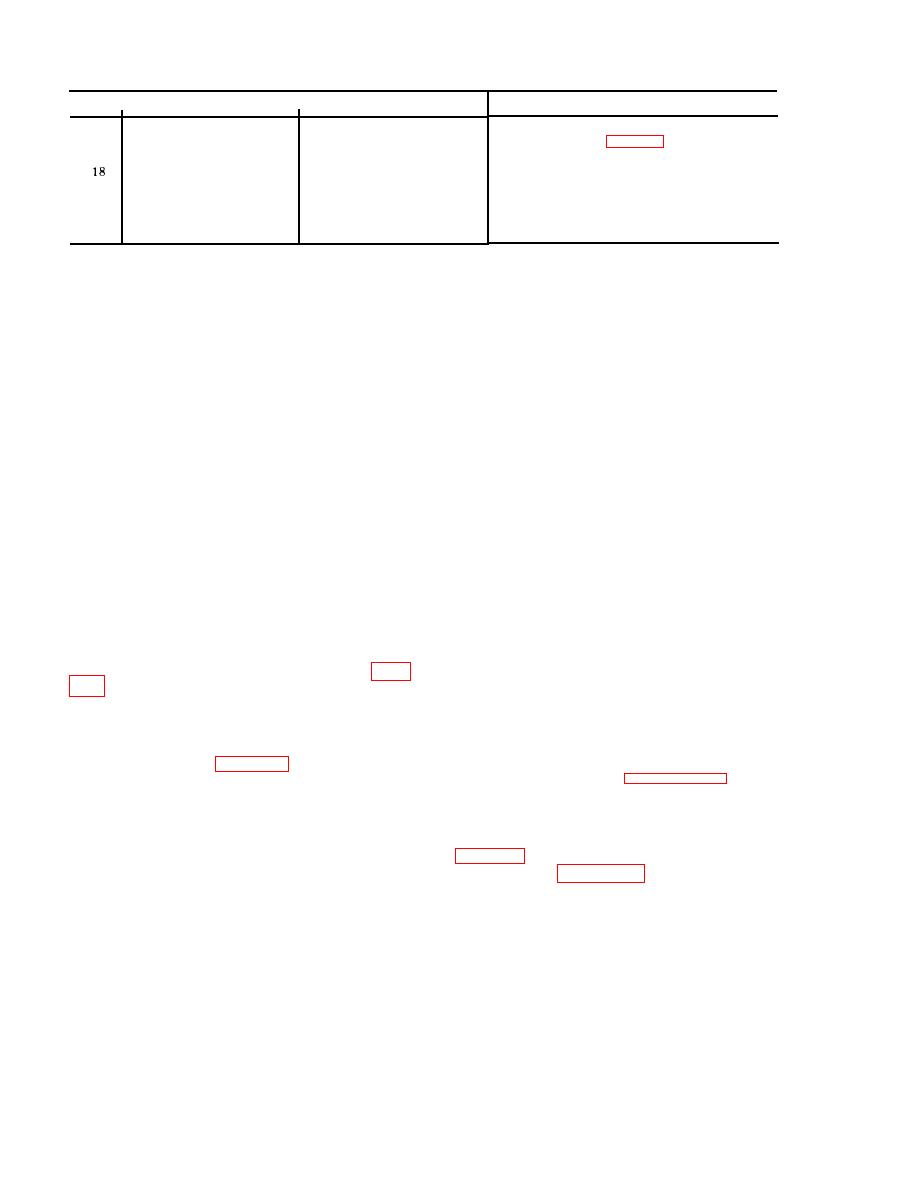

Procedure

Probable trouble

Indication

Item

I

Check transistors (fig. 23).

Audio amplifier Q12, Q13, or

Q14 defective.

Control unit LOOP switch Loss of 110-CPS reference

See item 15.

phase voltage on resolver

rotates bearing indica-

tor pointer in one direc-

servo motor B5.

tion only.

(4) L i s t e n f o r a u d i o o u t p u t s i g n a l i n

2-6. S i g n a l S u b s t i t u t i o n

headset. If. no signal is heard, check

a. General. S i g n a l s u b s t i t u t i o n p r o c e d u r e s

audio output transformer T20 and

help to localize trouble to a stage in the re-

capacitor C78.

ceiver. An externally generated signal is sub-

(5) Set audio oscillator output signal level

stituted for the signal normally present in each

to 850 millivolts and apply signal to

stage. The test equipment required for the

the collector of Q13. Audio output

tests in b through d below is listed in para-

from the headset should be as loud as

graph 2-3e. In the following tests, ground one

obtained in (4) above. If no sound

side of the audio oscillator or signal generator

is heard or output is low, check tran-

to the receiver chassis and conned the output

sistor Q14 and associated base signal

lead to the receiver test point indicated. When

input circuitry.

performing these tests, use the receiver main

(6) Set audio oscillator output signal to

schematic diagram (fig. 5-10 or 5-10.1.) in

33 millivolts and apply signal to the

conjunction with the parts location

base of Q13. Sound output should be

illustrations referenced in the following

procedures.

equal to that obtained in (4). If no

Caution: All circuits in the receiver are

sound is heard or sound level is weak,

transistorized. To avoid transistor damage, use

check transistor Q 13 and associated

tape or sleeving to cover the test leads except

circuit components.

for the extreme end required for testing,

(7) Adjust audio oscillator for an output

b. Audiofrequency Tests. Start these tests

of 42 millivolts and apply signal to

at the output of the last audio amplifier stage

the base of transistor Q12. Sound out-

and work back toward the first stage (figs.

put in headset should he equal to that

obtained in (4). If not, check transis-

fully clockwise.

tor Q12 and associated circuit com-

(1) Connect the receiver to Test Set, Di-

ponents.

rection Finder Set AN/ARM93 as

Note. After making the above tests, adjust

the variable resistor R82 in accordance with

shown in figure 22, but do not con-

the instructions in paragraph 3-17.

nect RF Signal Generator AN/URM

Tests. Start

the

25. Set the test set and control unit

c.

Intermediate

tests at the output of the last IF amplifier

controls as indicated in paragraph

stage and work back toward the first IF stage

2-5c. The range switch and TUNE

control may be set in any position.

resistor R90 (fig. 2-8) fully clockwise.

(2) Set Audio Oscillator TS-382/U to pro-

duce an audio output signal of 400

(1) Use the test setup described in p a r a -

graph 26b (1).

cycles at 5 volts rms.

(3) Using a 10-microfarad capacitor in

(2) Set RF Signal Generator A N / U R M - -

series with the audio oscillator out-

25 for a 142.5-kc output signal mod-

put lead, connect lead to the collector

ulated 30 percent at 400 cps. Adjust

of audio amplifier Q14.

output signal level to 50 millivolts.

2-22 Change 1

Previous Page

Previous Page