TM 11-4920-292-15

accuracy and repeatability test.

has been magnetically surveyed.

Monitor Assembly Telescope

Value for AREA COMP dervied

Alignment Test

from area magnetic survey is re-

a. Set up and level monitor assembly on

quired for use on following test,

tripod.

2. No personnel shall be within 10 feet

b. Rotate monitor to sight any distant target.

of turntable assembly or monitor

assembly when readings are being

c. Set azimuth scale to 0 degree 0 minute.

made.

NOTE

3. Heavy power equipment must be lo-

Monitor headings are set by loosening

cated at least 80 feet from turntable

lower clamp and rotating monitor to

assembly.

obtain desired setting on azimuth

11-16. Monitor Assembly Magnetic

scale. Lower clamp should then be

Alignment Test

tightened at desired heading and ver.

nier used to fine-adjust for exact

alignment of monitor scales. To set

NOTE

azimuth scale, upper clamp should

Monitor assembly is not set up initial-

be loosened and scale rotated to desired

ly but will be used later in test.

heading. Then upper clamp should be

tightened and vernier used to fine-

b. Set up and level turntable assembly at

adjust.

monitor location established during survey.

d. Rotate telescope 180 degrees in vertical

c. Mount magnetic azimuth reference detec-

plane.

tor on turntable assembly as shown in figure

e. Rotate monitor in horizontal plane to sight

some target.

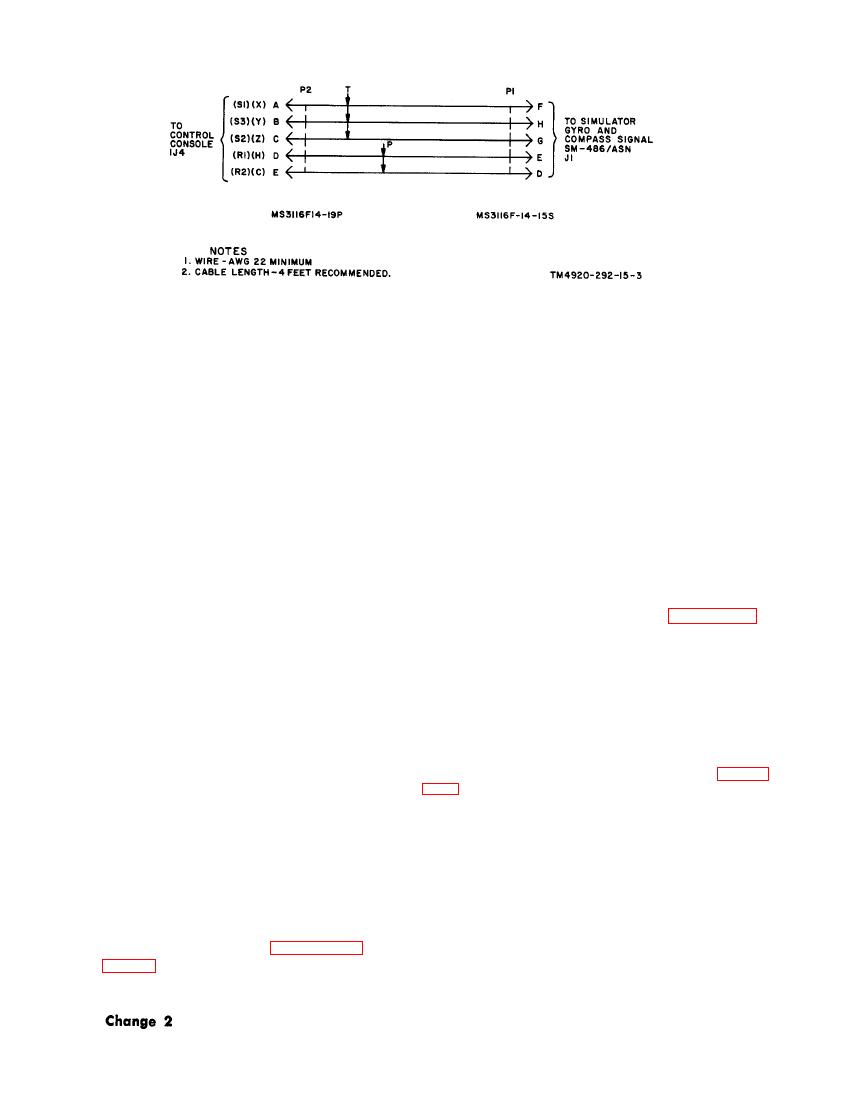

d. Connect cable W2 between control con-

sole connector 1J3 MONITOR and 4J1 of turn-

f. Bearing indicated on the azimuth scale

table assembly,

shall be 180 degrees 1 minute.

e. Set MODE SELECTOR switch to MON.

g. Return the telescope to its original posi-

tion in the vertical plane.

f. Set READOUT SELECT control to F.V.

g. Set POWER ON-POWER OFF switch to

NOTES

POWER ON.

1. All remaining tests (paragraph

h. Adjust VOLTS ADJUST control until

shall be performed in an area that

EXC VOLTS meter indicates 23.5 volts.

Previous Page

Previous Page