TM 11-6625-2440-12

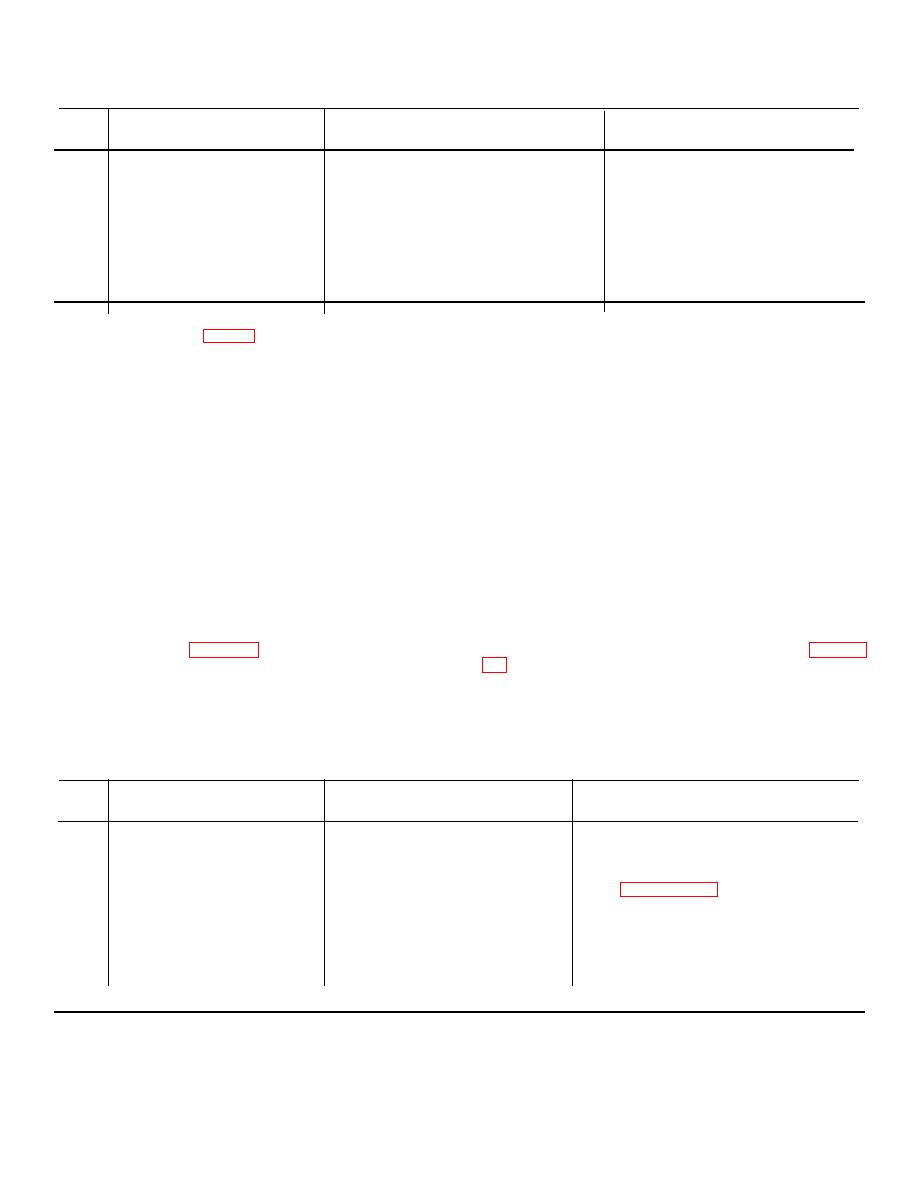

4-12. Quarterly Preventive Maintenance Checks and Services Chart

Seq

Symptom

Probable Cause

Corrective action

No.

1

Publications ...................................... Check that all publications are complete,

DA Pam 310-4.

serviceable, and current.

2

Modifications..................................... Check to see if new applicable MWO's

DA Pam 310-7

have been published.

All Urgent MWO's must be applied imme-

diately. Normal MWO's must be scheduled.

3

Spare parts ....................................... Check all spare parts for general condition

TM 11-6625-2440-20P.

and method of storage. There should be

no over-stock and shortages must be on

requisition.

a. Remove moisture and loose dirt with a clean

4-13.

Cleaning

WARNING

cloth.

b. Remove grease, fungus, and ground-in dirt

The fumes of trichloroethane are toxic.

Provide thorough ventilation whenever used;

with isopropyl alcohol.

c. Clean unpainted surfaces with trichloroethane.

DO NOT use near an open flame.

d. Remove dirt from hard-to-reach areas with a

Trichloroethane is not flammable, but

exposure of the fumes to an open flame

brush.

converts the fumes to highly toxic, dangerous

gases.

4-14.

Touchup Painting Instructions

CAUTION

Remove rust and corrosion from metal surfaces by lightly

Do not use trichloroethane on any painted or silk-

sanding with fine sandpaper, (FSN 5350-235-0124).

screened surface of the test set. Clean the front panel

Brush two thin coats of paint (FSN 8010-817-1213), on

and control knobs with a soft, clean cloth. If dirt is

the bare metal to protect from further corrosion. Refer to

difficult to remove, dampen the cloth with water and use

applicable cleaning and refinishing practices specified in

a mild soap. Clean exterior metal surfaces as follows:

TB 746-10.

Section III. TROUBLESHOOTING

4-15.

General Troubleshooting Information

abnormal indication or result is observed. When an

abnormal indication or result is observed, note the

Troubleshooting of this equipment is based upon the

sequence number and turn to the corresponding

self-test procedure (para 3-6). The self-test should be

sequence number in the troubleshooting chart (para 4-

performed after installation, monthly when in continuous

use, before each platform test when used intermittently,

troubleshooting chart. If the corrective actions indicated

or when the test set operational status is questionable.

do not result in correction of the trouble, a higher

Proceed through the tests in the self-test chart until an

category of maintenance is required.

4-16. Troubleshooting Chart

Seq

Symptom

Probable Cause

Remedial Action

No.

Note. Replacement of power supplies and

circuit cards requires removal of the

chaa,is from the combination case. Refer

1

Blower does not operate

Blower faulty

Refer to higher category of maintenance.

2

a. Voltage indicated for PLAT-

a. Circuit card 2A1A17 faulty

a. Replace circuit card 2AlA17 ( para 4-

FORM SCAN switch position

21).

1, 2, or 3 is 0 v.

4-3

Previous Page

Previous Page