TM 11-6625-2440-12

CHAPTER 3

OPERATING INSTRUCTIONS

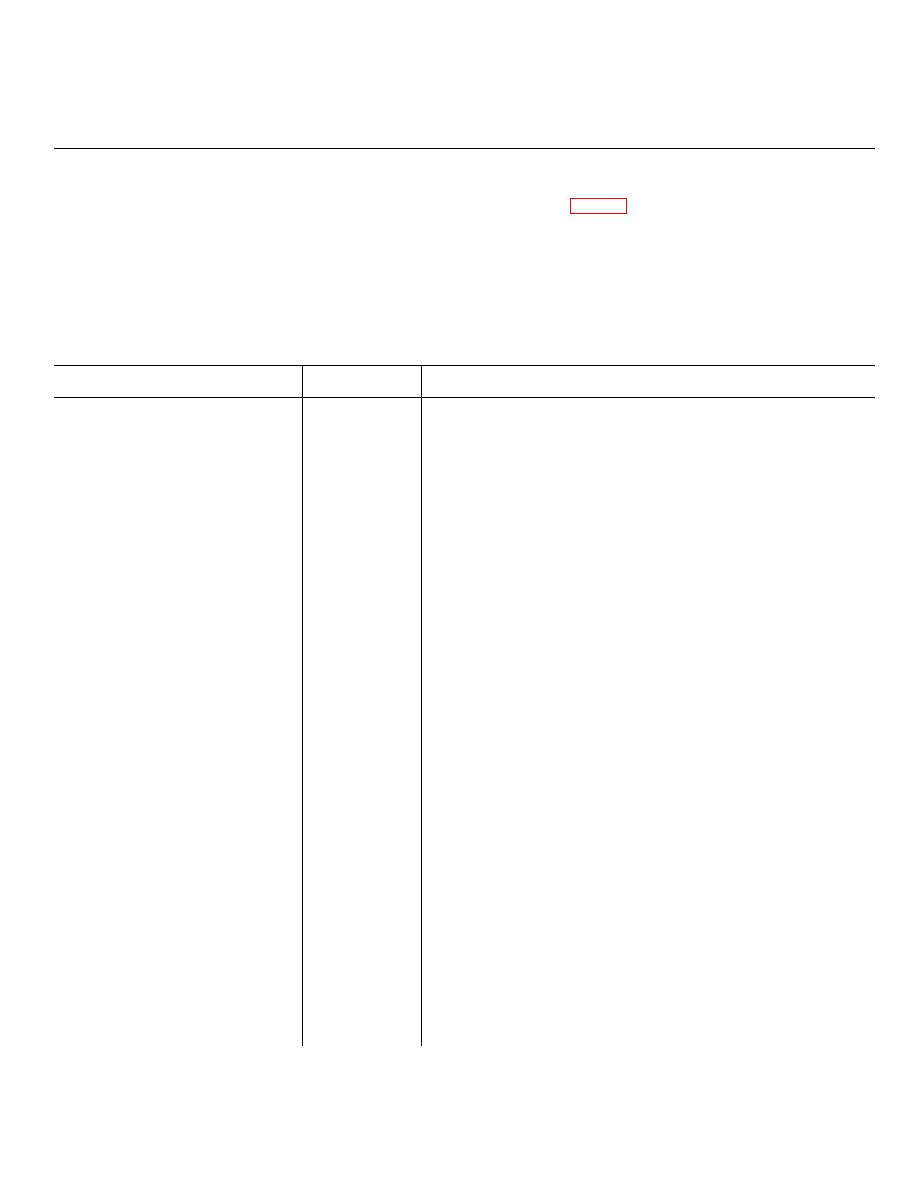

Section I. OPERATOR'S CONTROLS AND INDICATORS

indicators, and connectors with their reference

3-1. Damage From Improper Settings

designations and functional descriptions.

Unless

otherwise specified, functional descriptions relate to

No combination of control settings will cause damage to

operations within the test set. Control-display unit is

equipment or create a hazard to personnel.

abbreviated C-D unit in the chart.

3-2. Operating Controls and Indicators

a.

Control-Display Unit; Controls, Indicators, and

Control, indicator, or connector

Ref des

Function

28 VDC connector J2 --------------------------

1A1FL2

Provides input connection for 28 vdc test set operating power.

28 VDC PRIMARY circuit breaker----------

1A1CB2

Controls application of and provides overload protection for test set 28

vdc primary power.

28 VDC switch-----------------------------------

1A1S2

Controls application of primary 28 vdc and operating voltages to test set.

28 VDC indicator -------------------------------

1A1DS2

Indicates 28 vdc power is applied to test set.

115 VAC indicator ------------------------------

1A1DS1

Monitors C-D unit power supply +15 vdc output when 115 vac and 28

vdc power are applied to power supply.

115 VAC switch ---------------------------------

1A1S1

Controls application of 115 vac primary power to test set.

115 VAC PRIMARY circuit breaker --------

1CB1

Controls application of and provides overload protection for test set 115

vac primary power.

115 VAC 400 Hz 3PH connector J1 -------

1A1FL1

Provides input connection for 115 vac 400 Hz, 3-phase test set

operating power.

MODE switch ------------------------------------

1A1S3

OFF: Functions to inhibit platform power circuits and clear the test set

align mode control logic.

------------------------------------------------------

STBY: Functions to provide power to platform heaters, magnetic

heading servo, and part of transformer-buffer assembly and to clear

the test align mode control logic.

------------------------------------------------------

ALIGN: Provides the functions listed for STBY position and enables test

set and platform mode control logic to sequence through the align

mode. The phases of the align mode are cage (32 seconds), level

(2minutes), gyrocompass 1 (4 minutes), and gyrocompass 2 (no time

limit).

------------------------------------------------------

NAV: Inhibits platform AV inputs to test set velocity torque logic and

switches only earth rate correction signals to platform. Also latches

platform coarse heaters off.

------------------------------------------------------

AIR DATA: Functions to deenergize platform power supply and heaters

and to maintain operational status of platform magnetic heading

servo and part of transformer-buffer assembly.

CAGE switch-------------------------------------

1A1S11

HOLD: Provides switching to place and hold the test set and platform

mode control logic in the cage phase of align mode for 32 seconds

and until switched to OFF.

------------------------------------------------------

OFF: Permits test set and platform mode control logic to sequence

through cage phase of align mode.

CAGE indicator----------------------------------

1A1DS13

Lights when test set and platform mode control logic is in cage phase of

align mode.

LEVEL switch ------------------------------------

1A1S5

HOLD: Provides switching to place and hold the test set and platform

mode control logic in the level phase of align mode for 2 minutes and

until switched to OFF.

------------------------------------------------------

OFF: Permits test set and platform mode control logic to sequence

through level phase of align mode.

3-1

Previous Page

Previous Page